Inventory Return Tracking

This feature enables you to track and analyze the reason why serial numbers are being returned on invoices. It provides your inventory team a better sense of how many times product was actually handled and the reasons/outcome of each of those times. You can determine who has security to create and maintain the return tracking tables, who will maintain the inventory return screen, and who has access to the OE-46 Inventory Returns report.

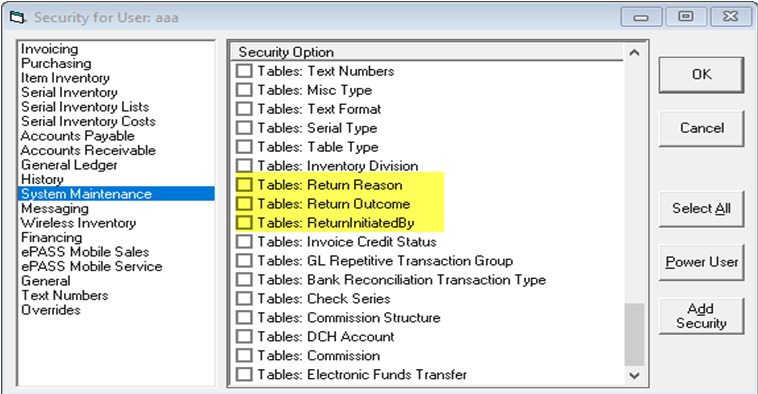

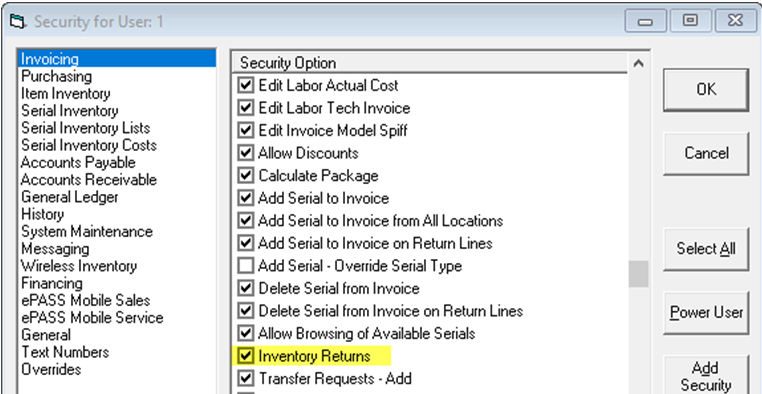

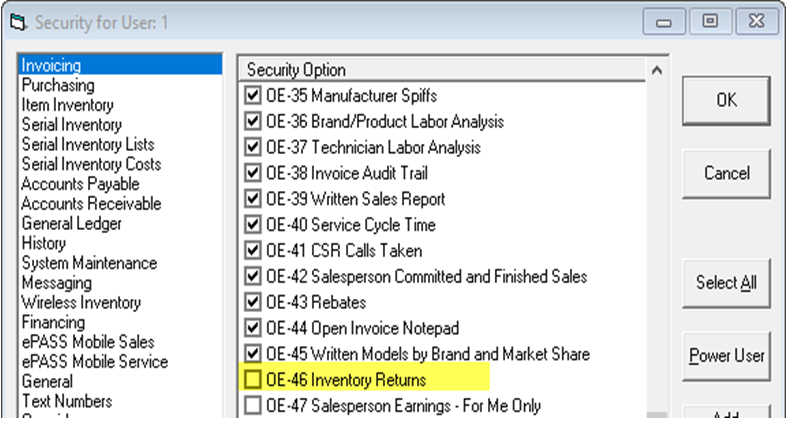

Security

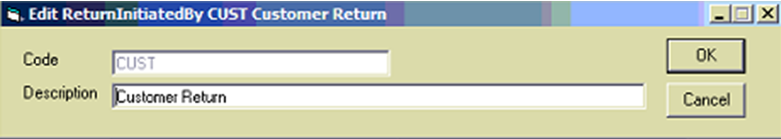

Setup Table

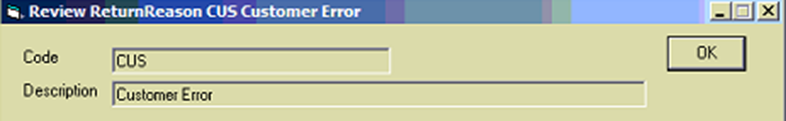

Return initiated by: Example: salesperson, customer

Return Reason: Example: damage, customer error, no fit, rescheduled

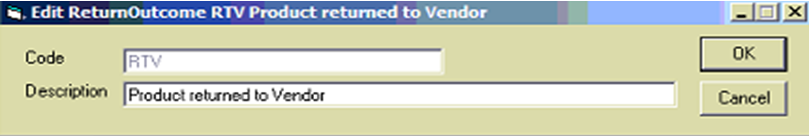

Return Outcome: Example: return to vendor, send to showroom floor

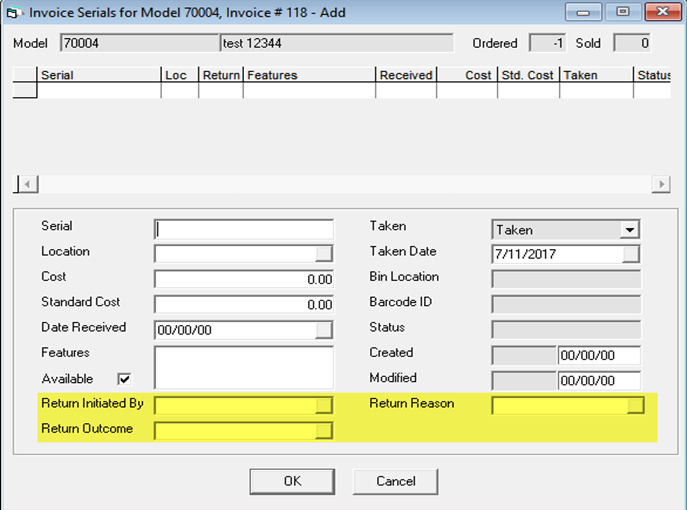

Invoice Model Serial

Adding a serial to a negative model line will show return initiated, return outcome & return reason field.

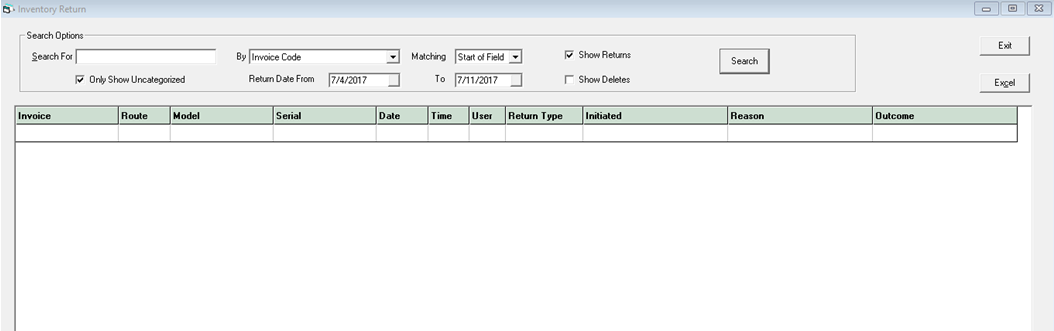

Inventory Return Maintenance

Invoicing > Inventory Returns

The inventory returns screen is where you can manage all returns/deletes, including inventory that just came back on the truck and was taken off the invoice and put back into the warehouse.

Search Options: Lets you search by various fields (invoice code, route code, model code, return initiated by, return outcome, return reason, user returned).

Any fields that might have been missed can be filled in by your inventory team which, if updated daily, will provide you with optimal reporting results.

Show Return: These have been returned on an invoice as negative line.

Show Delete: These have had the serial deleted from an invoice (positive line).

Returns will always reflect when a serial number has been returned as a negative line on an invoice because the original invoice it was sold on is status finished. For example, a customer exchange. Deletes will always reflect when the serial number has been deleted off an invoice that is still in status open. For example, a customer not home at time of delivery.

OE-46 Inventory Return Report

This report will let you analyze the returned/deleted serials, including summaries that compare shipping quantities to return quantities so you can analyze by salesperson, truck or supplier how many pieces are being shipped and, by reason, how many are being returned as well as what the percentage of returns per reason/truck/supplier.

You not only get the returns tracking, but also how much you shipped (which isn’t on any other report) so you get an overall warehouse/distribution performance report.