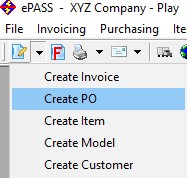

Start by clicking on Purchasing > Maintenance > Add or by clicking on the Quick Add toolbar option:

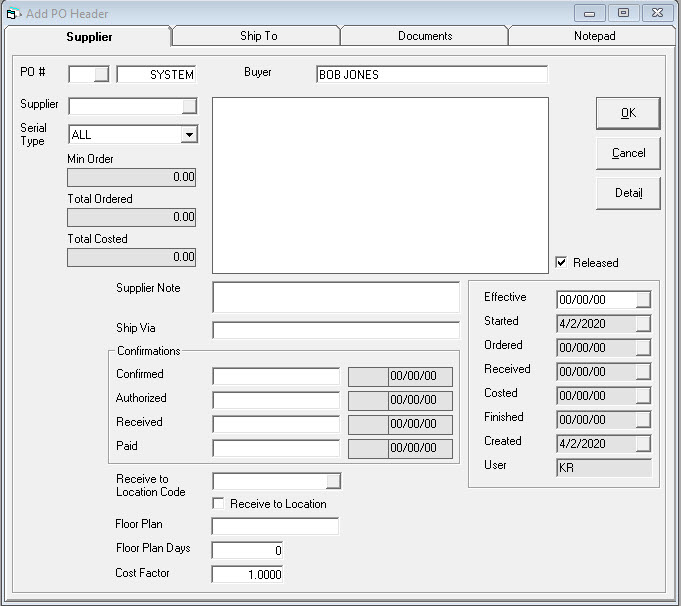

The first field is the PO # series followed by the PO #.

PO # Series (optional) can be defaulted by the supplier or at the terminal level. This allows different departments to have different PO numbering series, i.e. sales vs service.

PO # defaults to “SYSTEM” to take the next available number for this PO. This can be overridden and a number typed into the field “SYSTEM” is in.

This is the buyer name which can be defaulted by filling in the Salesperson Code in Tools > System Maintenance > Tables > User

The supplier you are ordering from. Start typing to see the suppliers available for selection. The name and address will populate along with any minimum order.

Populates from the supplier record and prints on the PO.

CONFIRMED: Note, user code entered, date

AUTHORIZED: Note, user code entered, date

RECEIVED: Note, user code entered, date

PAID: Note, user code entered, date

Location code where the pieces will be received. When Receive to Location is checked this will override any location selected on a scan gun. Only for models.

Note:

If the Supplier is set up with EDI, then you must choose a location that

is set up with EDI as well.

Note:

If the Supplier is set up with EDI, then you must choose a location that

is set up with EDI as well.

If this PO is floor planned, fill in the flooring company and this will be defaulted to serial numbers as the pieces are received.

The floor plan due date will be defaulted based on the days entered here.

If this PO has import duties or currency exchange the rate can be filled in here. For example, if the import duties add 25% to the cost of the inventory, then a piece that costs $100.00 will have a factored cost of $125.00. This is for both items and models.

If checked, this defaults all lines on the PO to be released. Checked is the default. If unchecked, all lines default to not released. To release some of those unreleased pieces, the split/release form in the PO detail screen allows lines to be split and marked if they have been released. Releasing can be used for large orders where you want to receive the inventory in stages or you are placing an advance order for seasonal product.

Effective date is no longer in use.

Date and time stamps of when the PO was started, ordered, received, costed, finished, created, and which user completed the action. This is the system date (the actual date).